“

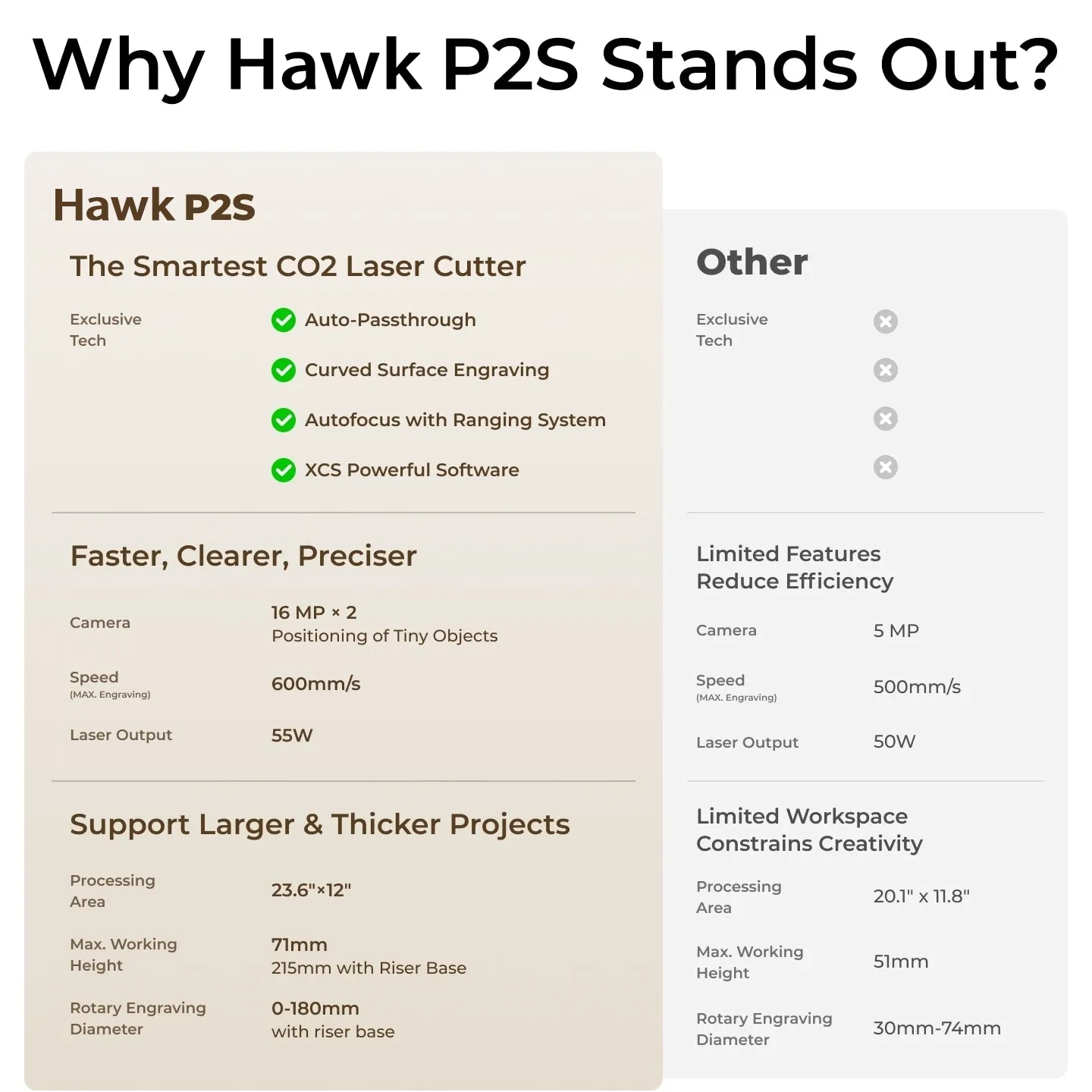

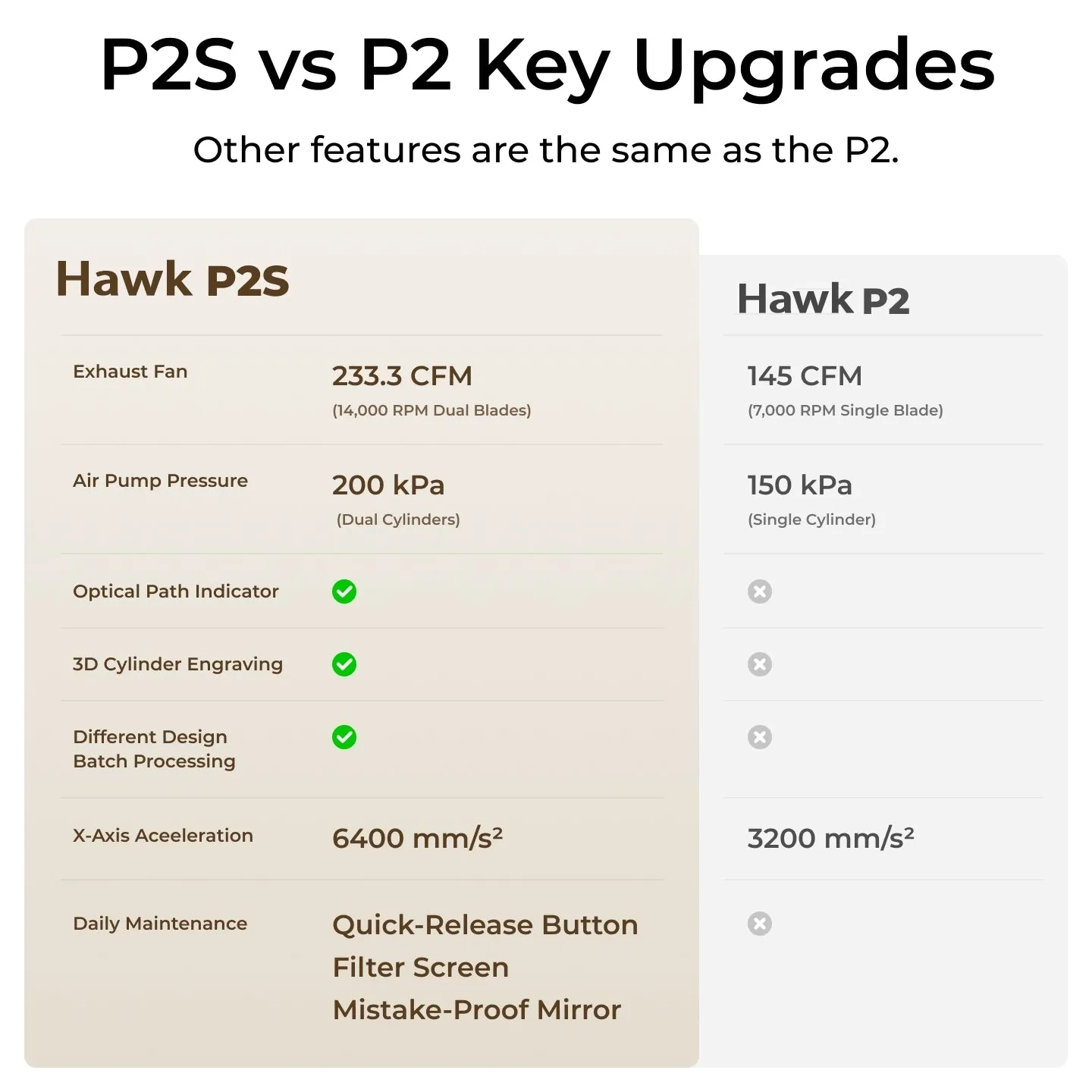

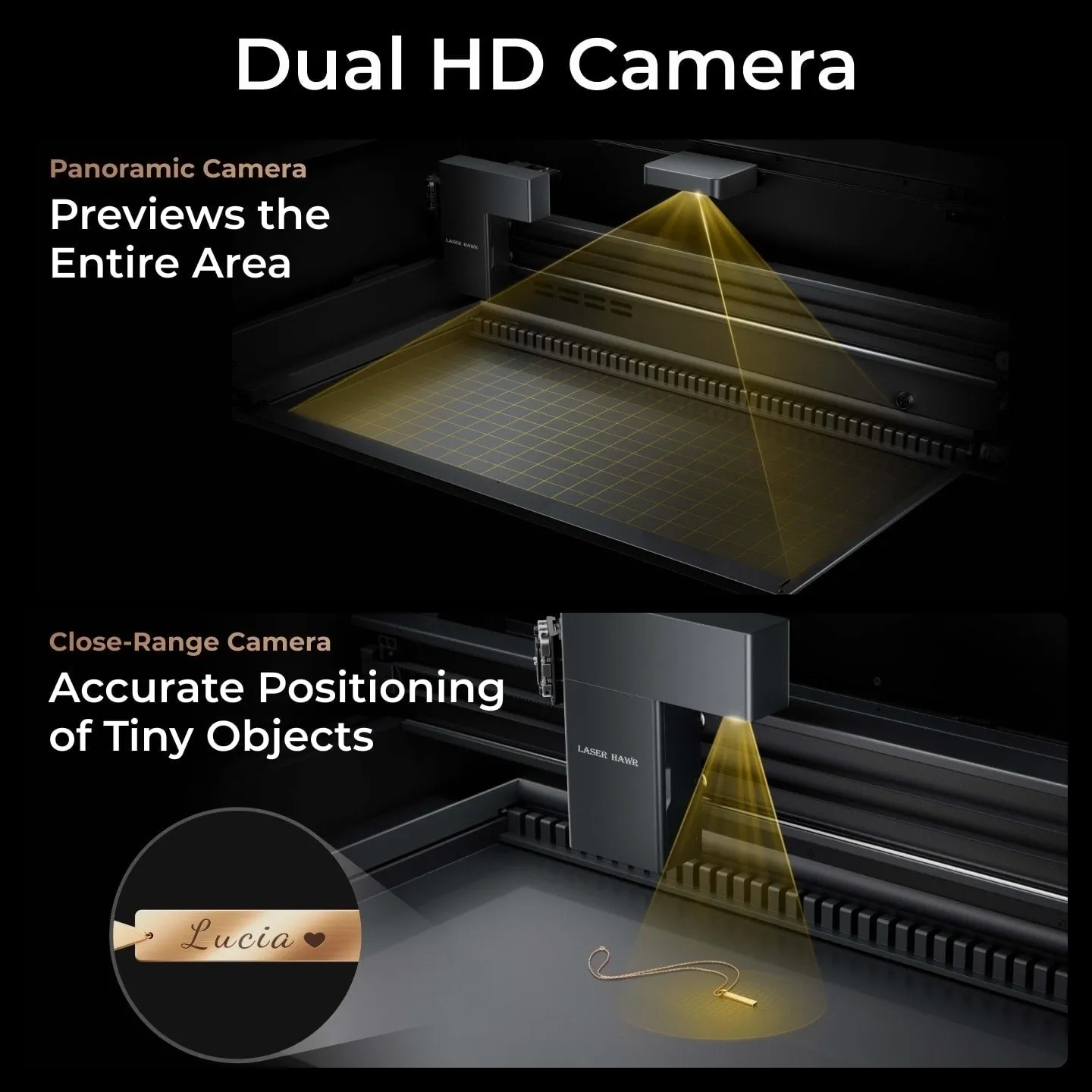

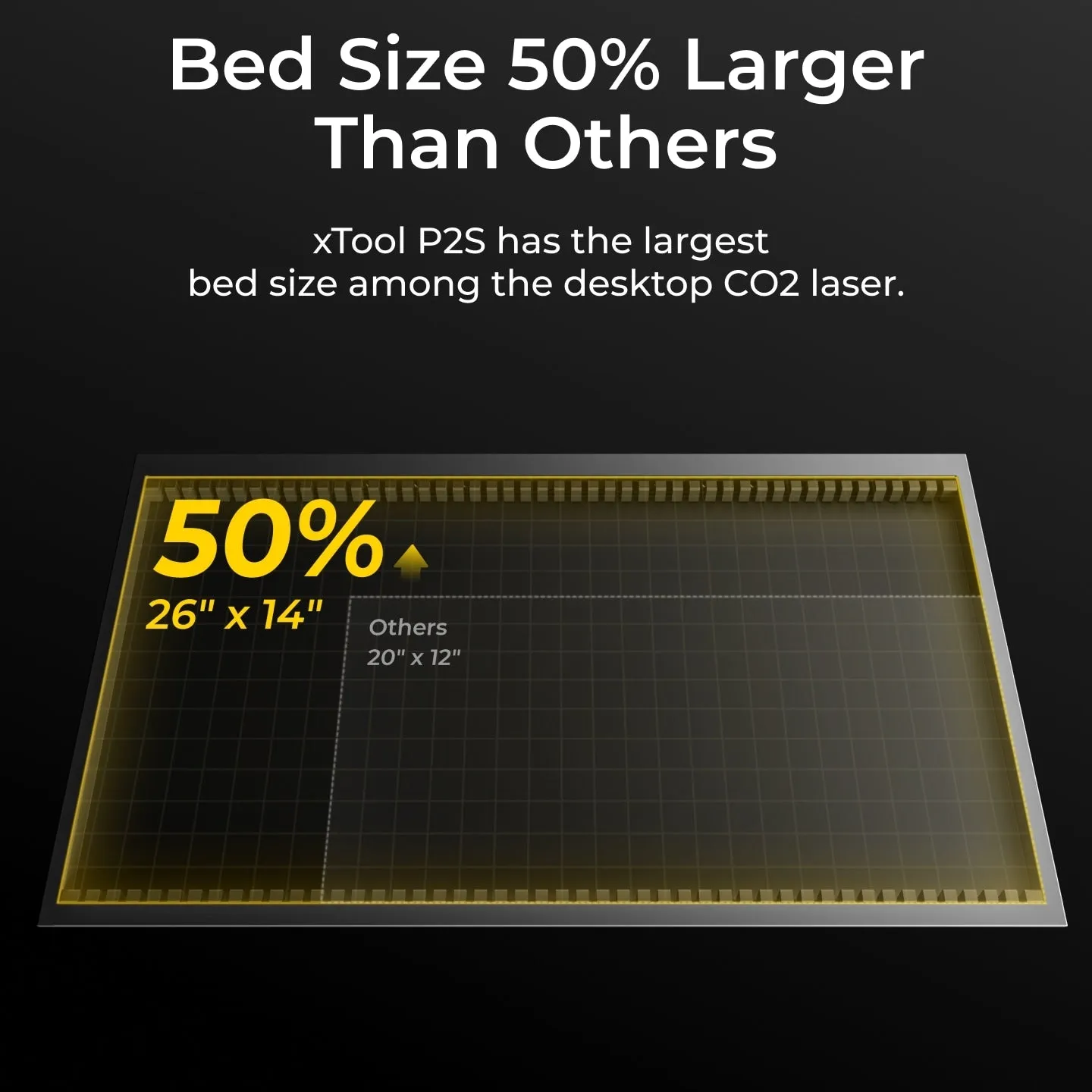

Introducing the Hawk P2S CO2 Laser Engraving Machine, a cutting-edge solution designed for precision, versatility, and efficiency in laser engraving and cutting applications. Whether you’re working with wood, glass, or other materials, this machine delivers exceptional performance, making it a must-have tool for professionals and hobbyists alike.

Key Features:

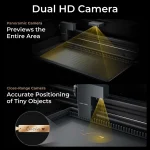

- Advanced CO2 Laser Technology: The Hawk P2S utilizes state-of-the-art CO2 laser technology, ensuring high precision and clean cuts for a wide range of materials, including wood, acrylic, and more.

- Optimized for Glass Laser Engraving: Achieve stunning, intricate designs on glass surfaces with ease. The machine’s precise laser control ensures smooth and detailed engravings every time.

- Titanium Dioxide Mix Compatibility: Designed to work seamlessly with titanium dioxide mix for laser engraving, this machine enhances the quality and durability of your engravings, especially on challenging surfaces.

- Versatile Laser Cutting and Engraving: From intricate designs to robust cutting tasks, the Hawk P2S handles it all. Its versatility makes it ideal for a variety of applications, including signage, crafts, and industrial use.

- User-Friendly Interface: Equipped with an intuitive control panel, the Hawk P2S ensures ease of use, even for beginners. Spend less time learning and more time creating.

Why Choose the Hawk P2S?

- Unmatched Precision: The machine’s advanced laser system ensures pinpoint accuracy, allowing you to create detailed and intricate designs with ease.

- Durability and Reliability: Built with high-quality components, the Hawk P2S is designed to withstand heavy use, ensuring long-term reliability and performance.

- Eco-Friendly Operation: The CO2 laser technology is energy-efficient and produces minimal waste, making it an environmentally friendly choice for your workspace.

Transform your creative projects with the Hawk P2S CO2 Laser Engraving Machine. Whether you’re engraving on glass, cutting through wood, or experimenting with titanium dioxide mix, this machine is your ultimate partner for precision and innovation.

More you like:

Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2 | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE | Best laser engraver ✓ Laser cutter engraver✓Laser engraving machines✓LaserHawk LH1 Pro | Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE | Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Laser for engraving machine✔ Laser engraver for wood✔ Hawk P2S CO2 cutter laser | Laser for engraving machine✔ Laser engraver for wood✔ Hawk P2S CO2 cutter laser

Richard Lopez –

I’m thoroughly impressed with this laser engraver! The precision and detail in the engravings are exceptional. The intuitive software and smooth operation make it a joy to use. It’s fast, reliable, and built with high-quality materials—perfect for both hobbyists and professionals. Highly recommend!

Robert Williams –

I’ve been using this laser engraver for months, and it’s exceptional! The engraving precision is flawless, even on intricate designs. The software is intuitive, and setup is a breeze. It’s fast, reliable, and built with high-quality materials. A must-have for professionals and hobbyists alike!

Miguel Smith –

Five stars for this laser engraver! The engravings are crisp and precise. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost my workflow. Top-notch build quality and reliability!

Christopher Takahashi (verified owner) –

**Laser Engraver Review: Custom Kitchenware Project**

**Specific Project Experience:**

– **Project Overview:** Utilized a laser engraver for a custom stainless steel kitchenware project, focusing on intricate patterns for a client’s cutlery line.

– **Challenges and Solutions:** Achieved consistent engraving depth by adjusting power settings to prevent discoloration and minimized overheating by optimizing speed. This resulted in precise, aesthetically pleasing designs that were previously challenging with traditional methods.

**Technical Performance:**

– **Hardware Capabilities:** The laser’s ability to handle reflective materials like stainless steel was key. It allowed for detailed engravings without damage.

– **Software Utilization:** Employed advanced software features such as vector optimization and raster engraving modes, enabling complex patterns and enhancing design precision.

**Business/ Creative Impact:**

– **Workflow Improvement:** The laser engraver significantly reduced production time and material waste, allowing for more efficient prototyping and faster turnaround times.

– **Customer Feedback and ROI:** Clients appreciated the high-quality finish, leading to increased orders and higher pricing for custom items. This resulted in a notable return on investment through expanded revenue streams.

**Comparison & Value:**

– **Efficiency Gains:** Compared to traditional methods like acid etching or manual engraving, the laser engraver offered superior speed and precision.

– **Cost-Effectiveness:** Despite initial investment costs, the tool provided long-term savings through reduced labor and material expenses, with a favorable payback period.

This review highlights how the laser engraver enhanced design capabilities, improved efficiency, and delivered positive business outcomes, solidifying its value in the industrial design workflow.

Juan Johnson –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation. Fast, efficient, and built to last. Highly recommend!”