Creality Laser Engraver – Unlocking the Potential of Laser Engraving Technology

Laser engraving technology has revolutionized the way we personalize and customize a wide range of materials. From leather goods to wooden surfaces, metal objects, and even glass, the applications of laser engraving are vast and versatile. At the forefront of this technological advancement is the creality laser engraver, a machine designed to meet the diverse needs of professionals and hobbyists alike. This article delves into the intricacies of laser engraving technology, the specifications and features of the creality laser engraver, material compatibility, safety considerations, industry best practices, cost-benefit analysis, maintenance tips, and project ideas to inspire your creativity.

Laser Engraving Technology and Applications

Laser engraving is a non-contact process that uses a high-intensity laser beam to vaporize the surface material of an object, creating precise and intricate designs. Unlike traditional engraving methods, laser engraving offers higher precision, speed, and versatility. The technology is widely used in various industries, including jewelry, personalization, arts and crafts, automotive, and even aerospace.

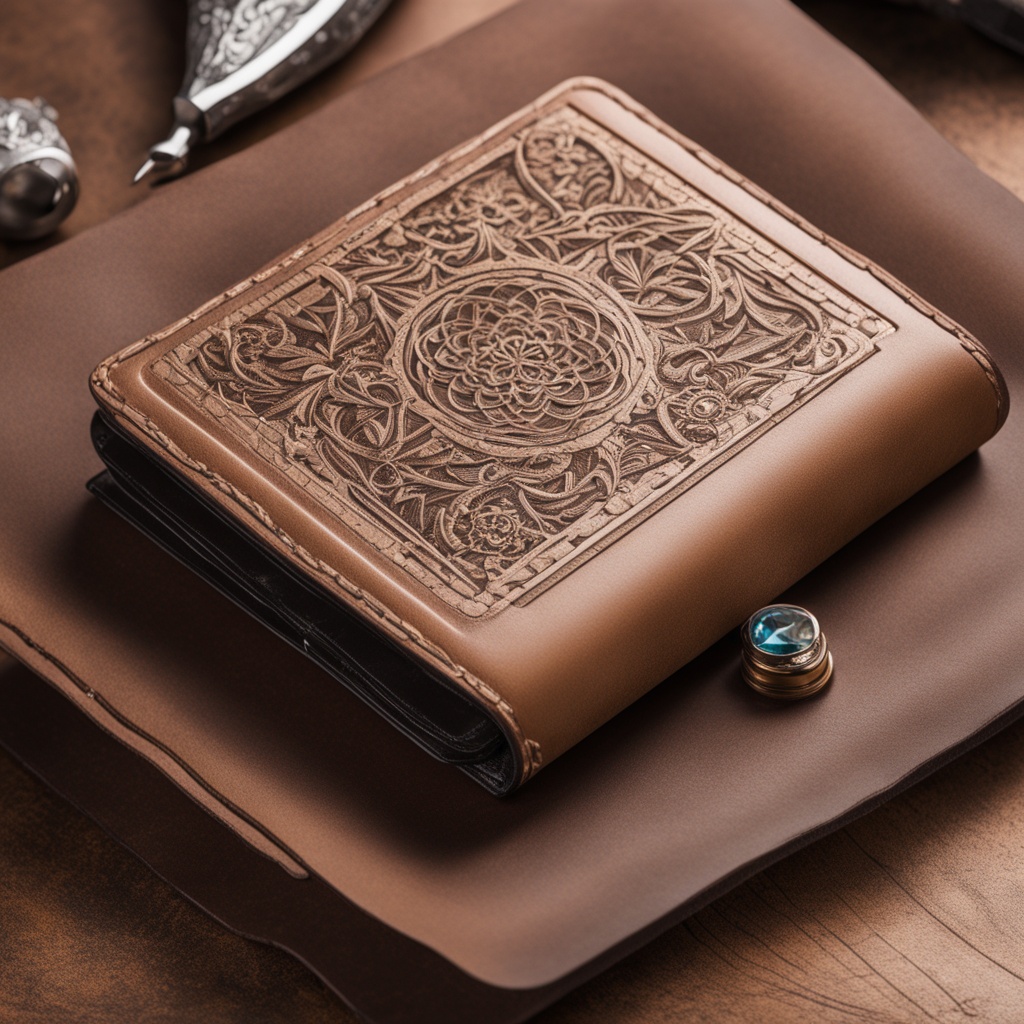

In the realm of personalization, the creality laser engraver excels in creating unique and customized designs on leather goods, such as wallets, purses, and phone cases. The machine’s precision allows for intricate patterns, monograms, and even photos to be etched onto the surface, adding a personal touch to everyday items.

Moreover, the technology is not limited to soft materials. Hard surfaces like wood, metal, and glass can also be engraved with equal precision. In the automotive industry, laser engraving is used to create custom logos and designs on interior parts, enhancing the aesthetic appeal of vehicles. Aerospace engineers utilize laser engraving for marking critical components, ensuring traceability and quality control.

Machine Specifications and Features

The creality laser engraver boasts an impressive array of specifications and features that cater to both beginners and professionals. With a compact design, the machine is easy to set up and operate, making it ideal for home workshops and small businesses.

- Laser Power: The machine comes with a high-power laser that can effectively cut and engrave a variety of materials. The power level can be adjusted to suit different materials and achieve the desired depth and detail.

- Engraving Area: The large engraving bed allows for larger projects, accommodating items up to a certain size. This makes it perfect for personalized gifts, prototypes, and small-batch production.

- Precision: The creality laser engraver is known for its precision, capable of creating intricate designs with minimal error. The machine’s advanced software allows for easy design imports and adjustments, ensuring perfect results.

- Software Compatibility: The machine is compatible with a wide range of design software, including Adobe Illustrator, CorelDRAW, and AutoCAD. This allows for seamless integration with existing workflows and easy design customization.

Material Compatibility

The versatility of the creality laser engraver lies in its ability to work with a wide range of materials. From soft leathers and woods to hard metals and glass, the machine can handle it all with precision and efficiency.

- Leather: Perfect for personalizing leather goods, the machine can create deep, clean cuts and intricate designs.

- Wood: Whether it’s plywood, MDF, or hardwood, the creality laser engraver can engrave and cut intricate patterns and text.

- Metal: With the right settings, the machine can engrave and mark metals such as stainless steel, brass, and aluminum.

- Glass: Laser engraving on glass creates a frosted effect, allowing for unique and elegant designs.

Safety Considerations

Operating a laser engraving machine comes with its own set of safety considerations. The creality laser engraver is designed with safety features to minimize risks, but users must still adhere to best practices to ensure safe operation.

- Eye Protection: Always wear laser-safe glasses when operating the machine to protect your eyes from laser radiation.

- Ventilation: Ensure proper ventilation in the workspace to prevent the accumulation of laser-generated fumes and particles.

- Fire Safety: Keep a fire extinguisher nearby and ensure that the workspace is free of flammable materials.

- Software Safety: Familiarize yourself with the machine’s software to avoid accidental activation of the laser.

Industry Best Practices

To achieve optimal results and maximize the lifespan of your creality laser engraver, it’s important to follow industry best practices.

- Regular Maintenance: Clean the machine regularly to remove dust and debris that can affect performance.

- Material Preparation: Ensure that materials are properly secured and aligned before starting the engraving process.

- Test Runs: Always perform a test run on scrap material before starting a project to ensure that settings are correct.

- Calibration: Regularly calibrate the machine to maintain precision and accuracy.

Cost-Benefit Analysis

Investing in a creality laser engraver can be a significant expense, but the benefits far outweigh the costs. The machine allows for personalized and customized products, which can fetch a higher price in the market. Additionally, the precision and speed of laser engraving make it a more efficient alternative to traditional methods.

In the long run, the creality laser engraver pays for itself through increased productivity and profitability. The machine’s versatility allows for a wide range of applications, making it a valuable addition to any business or home workshop.

Maintenance Tips

Proper maintenance is crucial for ensuring the longevity and performance of your creality laser engraver.

- Clean the Lens: Regularly clean the laser lens to remove dust and debris that can affect the beam quality.

- Lubricate Moving Parts: Use a suitable lubricant to keep moving parts operating smoothly.

- Check Belts and Pulleys: Ensure that belts and pulleys are tight and free of wear and tear.

- Regular Inspections: Perform regular inspections of all components to identify and address potential issues before they become critical.

Project Ideas and Tutorials

The creality laser engraver opens up a world of creative possibilities. Here are some project ideas and tutorials to inspire your creativity:

- Custom Leather Goods: Engrave monograms, logos, or personalized messages on leather wallets, purses, and phone cases.

- Wooden Decor: Create unique wooden signs, plaques, and coasters with intricate designs and text.

- Metal Jewelry: Engrave designs and text on metal jewelry pieces, such as bracelets, rings, and pendants.

- Glass Art: Explore the frosted effect of laser engraving on glass to create elegant and unique art pieces.