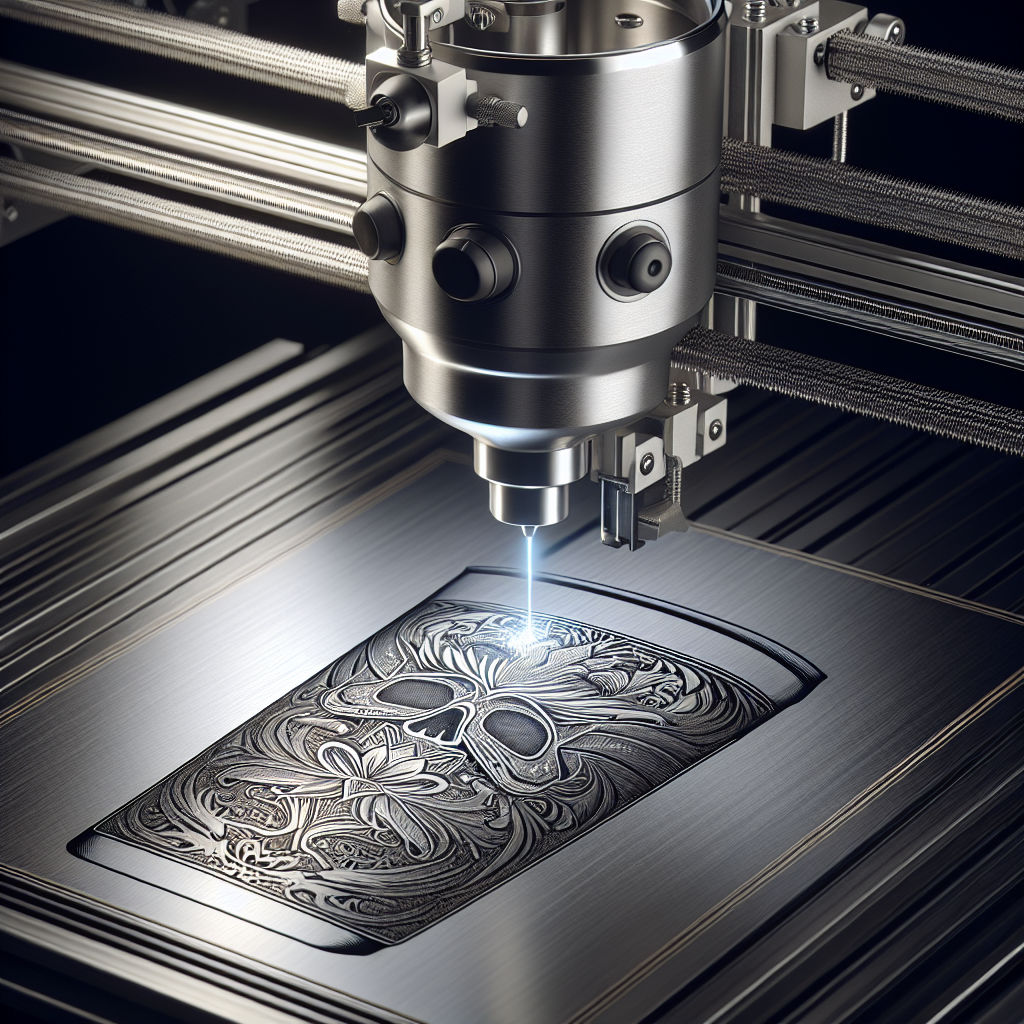

The Ultimate Guide to Tumbler Laser Engraving Machines: Precision, Versatility, and Innovation

What Is a Tumbler Laser Engraver?

A tumbler laser engraver is a specialized machine designed to etch intricate designs, logos, or text onto cylindrical objects like drinkware, bottles, and industrial components. Unlike flat-surface laser engravers, these systems feature rotating attachments or rotary axes that spin the workpiece during the engraving process. This ensures consistent precision across curved surfaces, making them indispensable for industries ranging from personalized gifts to manufacturing. With advancements in laser technology, modern tumbler laser engravers deliver unmatched accuracy, speed, and repeatability.

Why Choose a Tumbler Laser Engraving Machine?

The demand for customized products has skyrocketed, and businesses need tools that can keep up. A tumbler laser engraver offers unique advantages:

- 360-Degree Engraving: Achieve seamless designs on rounded surfaces without manual repositioning.

- Material Flexibility: Compatible with metals, plastics, glass, ceramics, and coated tumblers.

- High-Speed Production: Ideal for bulk orders, reducing turnaround time by up to 70%.

- User-Friendly Software: Intuitive interfaces allow even beginners to create professional-grade engravings.

But how do these machines compare to traditional engraving methods? Are they worth the investment? Let’s explore further.

Key Features to Look for in a Tumbler Laser Engraver

Not all laser engravers are built the same. When selecting a tumbler laser engraver, prioritize these features:

- Laser Power: Ranges from 20W to 100W. Higher wattage ensures deeper engravings on harder materials.

- Rotary Attachment Quality: Look for adjustable clamps and smooth rotation to avoid misalignment.

- Software Compatibility: Supports industry-standard formats like AI, DXF, and BMP.

- Cooling System: Essential for prolonged use; air-assisted or water-cooled options are common.

Pro Tip: Always test the machine’s compatibility with your target materials. For example, stainless steel tumblers require fiber lasers, while CO2 lasers excel on wood and acrylic.

Applications of Tumbler Laser Engraving Machines

The versatility of a tumbler laser engraver extends beyond drinkware. Industries leveraging this technology include:

- Retail and Promotional Products: Custom-branded merchandise for corporate events.

- Healthcare: Engraving surgical tools and medical devices with identification codes.

- Automotive: Marking parts for traceability and anti-counterfeiting.

- Art and Craft: Creating intricate designs on jewelry and decorative items.

Did you know? Some breweries use tumbler laser engravers to craft limited-edition bottles, enhancing brand loyalty.

How to Maintain Your Tumbler Laser Engraver

To ensure longevity and optimal performance, follow these maintenance tips:

- Clean the Lens Regularly: Dust and debris can scatter the laser beam, reducing precision.

- Inspect the Rotary Axis: Lubricate moving parts monthly to prevent wear and tear.

- Update Software: Manufacturers often release patches to improve functionality.

- Monitor Cooling Systems: Overheating is a common cause of laser tube failure.

Question: What happens if you ignore maintenance? Expect frequent breakdowns and costly repairs.

The Future of Tumbler Laser Engraving Technology

Innovation in the laser engraving sector shows no signs of slowing. Emerging trends include:

- AI Integration: Smart systems that auto-adjust settings based on material scans.

- Eco-Friendly Lasers: Reduced energy consumption and safer emissions.

- 3D Engraving Capabilities: Adding depth to designs for tactile finishes.

With these advancements, the tumbler laser engraver will continue to dominate markets requiring precision and customization.

Frequently Asked Questions

Q: Can a tumbler laser engraver work on irregularly shaped objects?

A: Yes, provided the rotary attachment can secure the item firmly. Adjustable clamps are critical for odd geometries.

Q: How long does it take to engrave a standard 20 oz tumbler?

A: Depending on design complexity, it takes 2–10 minutes. High-power lasers like the tumbler laser engraver LaserHawk LH1 Pro 9 can cut this time by half.

Q: Is specialized training required to operate these machines?

A: Basic training suffices for simple projects, but mastering advanced techniques may require courses.

Conclusion

The tumbler laser engraver is a game-changer for businesses and creators seeking to elevate their customization capabilities. From unmatched precision to broad material compatibility, this technology empowers users to turn ordinary objects into extraordinary works of art. Ready to revolutionize your production line? Explore advanced models today and unlock endless creative possibilities.