Understanding the Laser Engraver Cutter: Precision and Versatility in Modern Machining

**Laser engraving technology has revolutionized the way we approach precision machining and material processing.** At its core, a is a powerful tool that combines cutting-edge laser technology with advanced software to create intricate designs, patterns, and text on various materials. Whether you’re working in manufacturing, art, or custom fabrication, understanding the capabilities of this machine can open up endless possibilities for your projects.

## What Is a Laser Engraver Cutter?

A is a multifunctional device that uses a focused laser beam to etch, cut, or intricate designs onto materials such as wood, metal, plastic, glass, and more. Unlike traditional machining methods, this machine offers unparalleled precision, speed, and versatility. The laser beam’s intensity can be adjusted to suit different materials and depths of engraving, making it an ideal tool for both small-scale crafts and large-scale industrial applications.

The machine typically consists of a laser source, optics for focusing the beam, a control system, and software for designing patterns. **The key advantage of this technology is its ability to perform highly accurate and repeatable operations without causing damage to the surrounding material.** This makes it a favorite among artists, manufacturers, and hobbyists alike.

## Applications of Laser Engraver Cutters

The versatility of a allows it to be used in a wide range of industries. Here are some of the most common applications:

- Custom Engraving: Personalized items such as jewelry, name plates, and promotional products can be created with intricate designs.

- Metal Cutting: Precision cutting of metals for manufacturing parts, automotive components, and decorative items.

- Fabrication: Creating custom signs, plaques, and architectural elements with detailed engravings.

- Artistic Expression: Artists use laser engravers to create unique works of art on various materials.

- Packaging and Labeling: High-precision labeling for products in the food, pharmaceutical, and cosmetics industries.

These applications highlight the machine’s ability to handle both simple and complex tasks with ease. Whether you’re working on a small-scale project or large-scale production, the is a valuable asset.

## Advantages of Using a Laser Engraver Cutter

The adoption of laser engraving technology offers numerous benefits over traditional methods:

- Precision: The laser beam’s high focus allows for detailed engravings with micron-level accuracy, ensuring every design is perfectly executed.

- Speed: Compared to manual engraving or mechanical cutting, laser processes are significantly faster, reducing production time and increasing efficiency.

- Versatility: The machine can work with a wide range of materials, making it suitable for diverse applications across industries.

- Non-Contact Processing: Unlike mechanical tools that physically touch the material, laser engraving is a non-contact process, minimizing the risk of damage or deformation to the workpiece.

- Eco-Friendly: Laser engraving produces minimal waste and reduces the need for harmful chemicals, making it an environmentally friendly option.

These advantages make the a must-have tool for anyone looking to enhance their machining capabilities.

## Choosing the Right Laser Engraver Cutter

Selecting the right laser engraver cutter depends on your specific needs, budget, and the types of materials you’ll be working with. Here are some factors to consider:

- Type of Laser: Different lasers (CO2, fiber, or crystal) are suited for different materials. For example, CO2 lasers are ideal for non-metallic materials like wood and plastic, while fiber lasers excel at cutting metals.

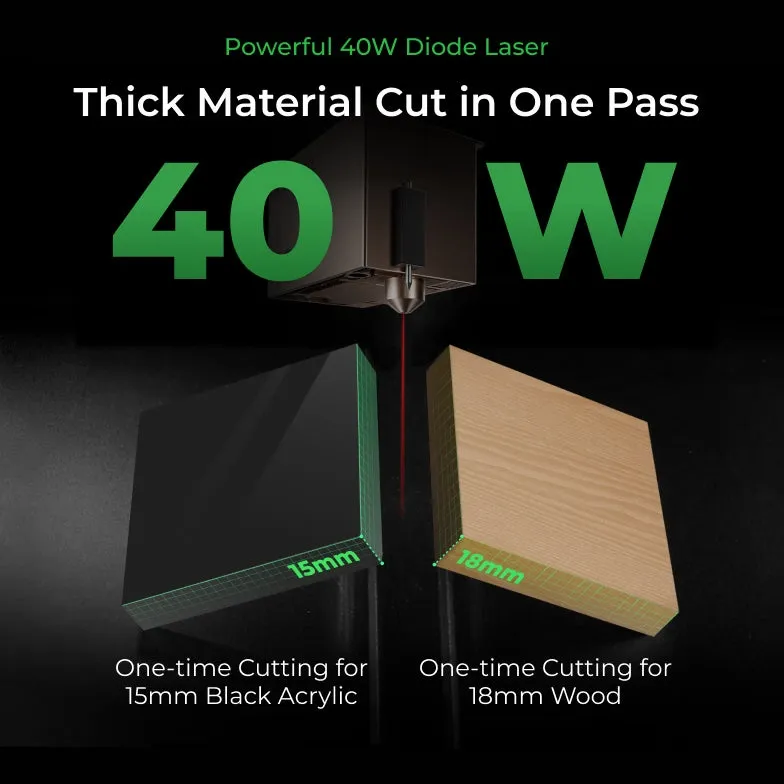

- Power Output: Higher power output is necessary for thicker materials or faster processing times. However, lower power may suffice for delicate or thin materials to avoid overheating.

- Software Compatibility: Ensure the machine supports popular design software like CAD or Adobe Illustrator for seamless integration into your workflow.

- Budget: Laser engraver cutters come in a wide price range, from affordable hobbyist models to high-end industrial machines. Determine your budget before making a purchase.

By evaluating these factors, you can choose a machine that perfectly aligns with your project requirements and helps you achieve optimal results.

## Maintenance and Safety Considerations

While laser engraver cutters are robust machines, proper maintenance is essential to ensure their longevity and performance. Regular cleaning of the optics, checking the alignment of the laser beam, and replacing worn-out components can prevent costly downtime and extend the machine’s lifespan.

Safety should also be a top priority when operating a . Always wear protective eyewear to shield your eyes from the laser beam, and ensure the work area is well-ventilated to avoid inhaling fumes generated during the engraving process. Proper training and adherence to safety protocols are crucial for safe operation.

## The Future of Laser Engraving

As technology continues to advance, laser engraving systems are becoming more sophisticated and accessible. Innovations such as AI-driven software, automated calibration, and integrated sensors are enhancing the precision and efficiency of these machines further. Additionally, the growing demand for sustainable manufacturing practices is driving the development of eco-friendly laser engraving solutions.

With its wide range of applications and ever-improving technology, the is poised to remain a cornerstone of modern machining for years to come.

## Conclusion

In summary, a is a versatile and powerful tool that has transformed the way we approach precision machining and material processing. Its ability to create intricate designs with high accuracy, speed, and minimal waste makes it an invaluable asset for professionals and hobbyists alike.

If you’re considering investing in this technology, take the time to research different models and consult with experts to find the best option for your needs. With proper maintenance and safe operating practices, a laser engraver cutter can provide years of reliable service and help bring your creative vision to life.